Karl Klein Ventilatorenbau GmbH - Industrieventilatoren

The Karl Klein Group - impressive diversity

Competence in radial fan construction/process fans for series production and the manufacturing of individual parts • Technologies for standardisation and niche applications • Customer-oriented CAD design • Development with flow simulation and impeller calculation • Flexibility through high vertical range of manufacture • Fast response times • Short delivery times for complex products • Our little ones can do what the big ones can do!

Low-pressure type NHV high performance fan

Volume flow from 696 to 72000 m³/h (24579 to 2542656 ft³/h) - Pressure from 1158 to 12000 Pascal

Application

- Milling technology

- Process technology in the fields of process engineering, transport of dusts, environmental engineering

- Cooling systems

- Drying systems

Standard

- 2 or 4-pole

- Highly efficient impellers

- Sheet steel housing

- Clockwise or counterclockwise

- Frequency controllable

Optional

- Clutch drive

- Comprehensive range of accessories

- Stainless steel (V2A, V4A)

- For hot air up to 600°C (1,112°F) in continuous operation

- ATEX zone 1, 2, 21 or 22 (for media temperature between -20°C (-4°F) and +60°C (140°F))

Technical description of the high-performance fan shown here

- Developed for use in the food sector (FDA-compliant).

- With measuring nozzle (k-value) for determining and controlling the volume flow.

- Drive: 30 kW, IE3, 2-pole, 380/660 V, 50 Hz, Iso class F, IP 55, IM B3, PTC thermistor, CEL.

- This high-performance fan delivers 27,200 m³/h (960558.93 ft³/h) of air with a static pressure difference of 5,090 Pascal.

- FDA-compliant paint finishes in white aluminum.

- Incl. base frame.

- Housing welded steel, with cleaning hole.

- The impeller is made of high-strength steel of 1.0570 (also known as ST52-3) blades of high-strength 1.8928 (fine-grained structural steel with very high yield strength) from our subsidiary Kamptmann.

- Suitable for air containing dust (e.g. flour).

- The dimensions of the complete fan with accessories are (HxLxW) 1.82 m x 1.85 m x 1.27 m. (5.97 ft x 6.07 ft x 4.17 ft)

High-performance fan with belt drive

We can manufacture almost any fan with V-belt design.

- The high-performance fan shown here is a special version.

- The complete fan is completely insulated against heat in the final version.

- The installation site is Mexico.

Technical description

- The drive is equipped with a three-phase motor with 160 kW power, 2-pole, 460/795V, 60 Hz, Iso class H; IP 55 with bimetal.

- The drive is equipped with a three-phase motor with 160 kW power, 2-pole, 460/795V, 60 Hz, Iso class H; IP 55 with bimetal.

- The shaft is sealed with a carbon floating ring seal.

- The fan impeller is made of a high-temperature steel of 1.8928 NAXTRA 700 by our subsidiary Kamptmann itself.

- This high-performance fan delivers 50,300 m³/h (1,776,327.7 ft³/h) of air with a static pressure difference of 14,000 Pascal.

- The dimensions of the complete fan are 2.70 m x 1.94 m x 1.40 m (8.86 ft x 6.36 ft x 4.59 ft).

- In the final design, the fan was insulated with 150 mm (5.90 in) insulation against heat.

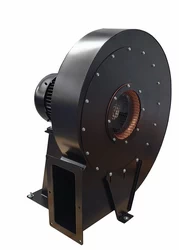

DMVL (3-phase) / EMVL (1-phase) type medium pressure centrifugal fans with high performance impellers

Volume flow from 400 to 3000 m³/h (14125 to 10944 ft³/h) - Pressure from 1400 to 7000 Pascal

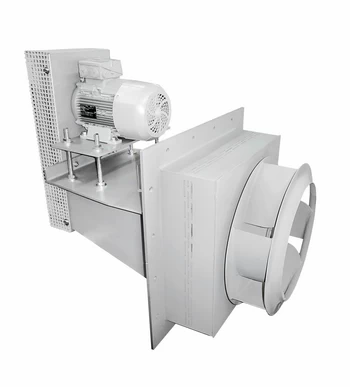

The new Flexline series - flexible and short delivery times - Type FLN

Volume flow from 2000 to 20000 m³/h (70629 to 706293 ft³/h) - Pressure from 1200 to 2500 Pascal

- The fan range includes 18 different types.

- The housings consist of a frame construction with four legs and are designed for an output of 0.55 to 30 kW and volume flows of 2,000 to 46,000 m³/h (70,629.33 to 1,624,474.7 ft³/h).

- The product range developed at the main plant in Aichwald sets in-house standards as a result of the close cooperation within the Karl Klein Group—especially with regard to the impellers and nozzles produced by the Kamptmann subsidiary in Crailsheim. This supports the customer in the variety of application possibilities.

- No more long delivery times

- New, flexibly mounting standard series enables fast throughput of production

- The fan types classified as centrifugal fans with impeller diameters from 355 to 900 mm (13.98 to 35.43 in), composed of components manufactured in series. The product range has devices for every industry application and is also available in an ATEX directive-compliant version. The use of high-quality standard components significantly reduces manufacturing lead times, so that even faster response times can be achieved from order receipt to delivery.

Large-volume centrifugal fans—from our factory in Petersberg/Thuringia

Volume flows up to 650,000 m³/h (22,954,533.4 ft³/h) and pressure differences up to 25,000 Pa

Special features:

- Volumetric flows up to 650,000 m³/h (22,954,533.4 ft³/h)

- Pressure differences up to 25.0 kPa

- Driven by belt, clutch or directly

- Heavy industrial version

- Painting according to customer requirements

- Media temperatures up to max. 650°C (1202°F)

- Housing jacket for sound insulation

- Split housing halves

- Fold-out impeller

- ATEX versions (for media temperatures between -20°C (-4°F) and +60°C (140°F))

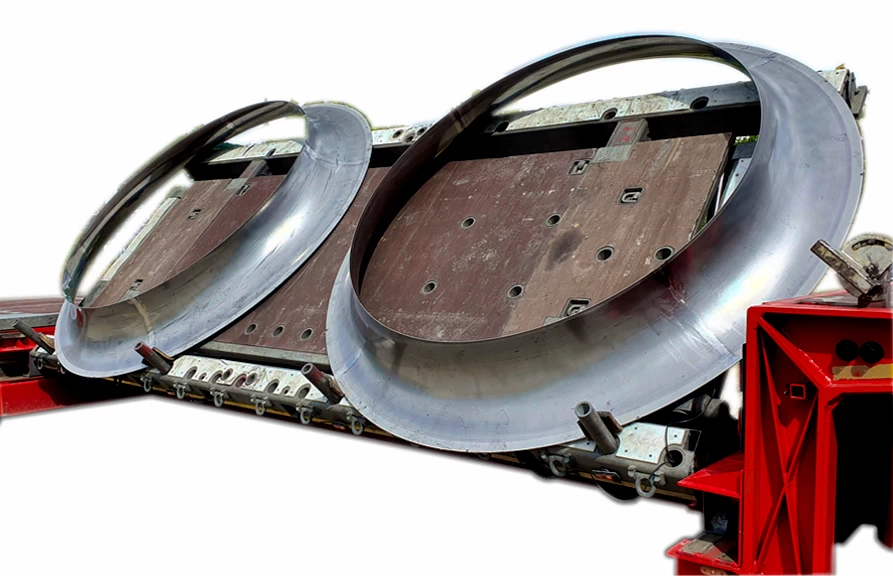

Large spun parts

Free-running centrifugal fans

Volume flows up to 250,000 m³/h (8,828,666.68 ft³/h) and pressure differences up to 3,500 Pa - max. rotor diameter 2,000 mm

Special features

- Backward curved high-performance impellers from own production

- Impeller diameter max. 2,500 mm (98.43 in)

- Media temperatures up to max. 650°C (1,112°F), if necessary with insulation box

- Application-optimized material selection, e.g. sheet steel, stainless steel, N-A-XTRA®

- Mounting plates according to customer requirements

- Driven by belt or directly

- ATEX versions (for media temperatures between -20°C (-4°F) and +60°C (140°F))

Gas-tight fans

Sound insulation measures

Sound insulation box - shown here open on 2 sides

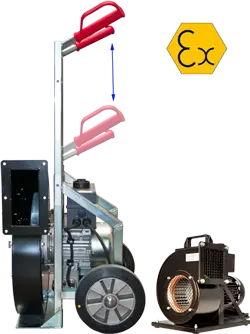

Mobile transportable fans—MRV type

Cast iron fans (gray cast iron)

Transport fans (gray cast iron)

Fans with split-phase motors

performance of air from 16 until 77 m³/h - pressure from 51 until 165 Pascal

External rotor fans

performance of air from 114 until 438 m³/h - pressure from 144 until 586 Pascal

Low-pressure fans with drum impellers - Type DNG (3- pole) / ENG (1- pole)

performance of air from 72 until 7000 m³/h - pressure from 180 until 2300 Pascal

DMV/DMVL (3-phase) / EMV/EMVL (1-phase) type medium pressure centrifugal fans

Volume flow from 54 to 6000 m³/h (1907 to 211888 ft³/h)- Pressure from 250 to 8000 Pascal

High pressure fans type HHV and DHV (with frequency converter)

Volume flow from 338 to 12000 m³/h (11936 to 423776 ft³/h) - Pressure from 3134 to 32000 Pascal

Area of application:

- Power plant operations

- Industrial furnace construction

- Filter technology

- Test bench technology

- Process technology in the fields of biogas, vacuum technology, chem. industry, process technology

Special features

- Speeds up to 130 Hz

- Frequency inverter mounted or as control cabinet version

- Impellers made of aluminum (for ATEX: steel)

ATEX centrifugal fans zone 1 and 2

Fields of application

- Biogas plants

- Environmental technology

- Warehouse equipment

- Shipbuilding

- Electric heaters

- Extraction systems

- Clean room technology

- Filling systems

Special features

- Gas Explosion Zone 1 and 2

- Explosion groups IIA, IIB and IIC according to DIN EN 14986

- Temperature class T3, temperature class T4 - T6 available on request

- Frequency inverter operation

- Non-electrical devices according to DIN EN 13463 part 1 and 5

- Documentation for drive (electrical part) and fan (non-electrical part)

ATEX centrifugal fans zone 21 and 22

Spezifikationen

- Dust Explosion Zone 21 and 22

- Explosion groups IIIA, IIIB and IIIC according to DIN EN 14986

- Temperature class T 125 °C

- Frequency inverter operation

- Non-electrical devices according to DIN EN 13463 part 1 and 5

- Documentation for drive (electrical part) and fan (non-electrical part)

- Explosion protection for media containing dust in the fan or in the vicinity of the fan