Frequency converters

Frequency converters - intelligence for fans

Our fans can be equipped with a frequency converter mounted directly on the motor terminal box up to a motor power of 22.0 kW. Single-phase fed types are also available up to 1.1 kW.

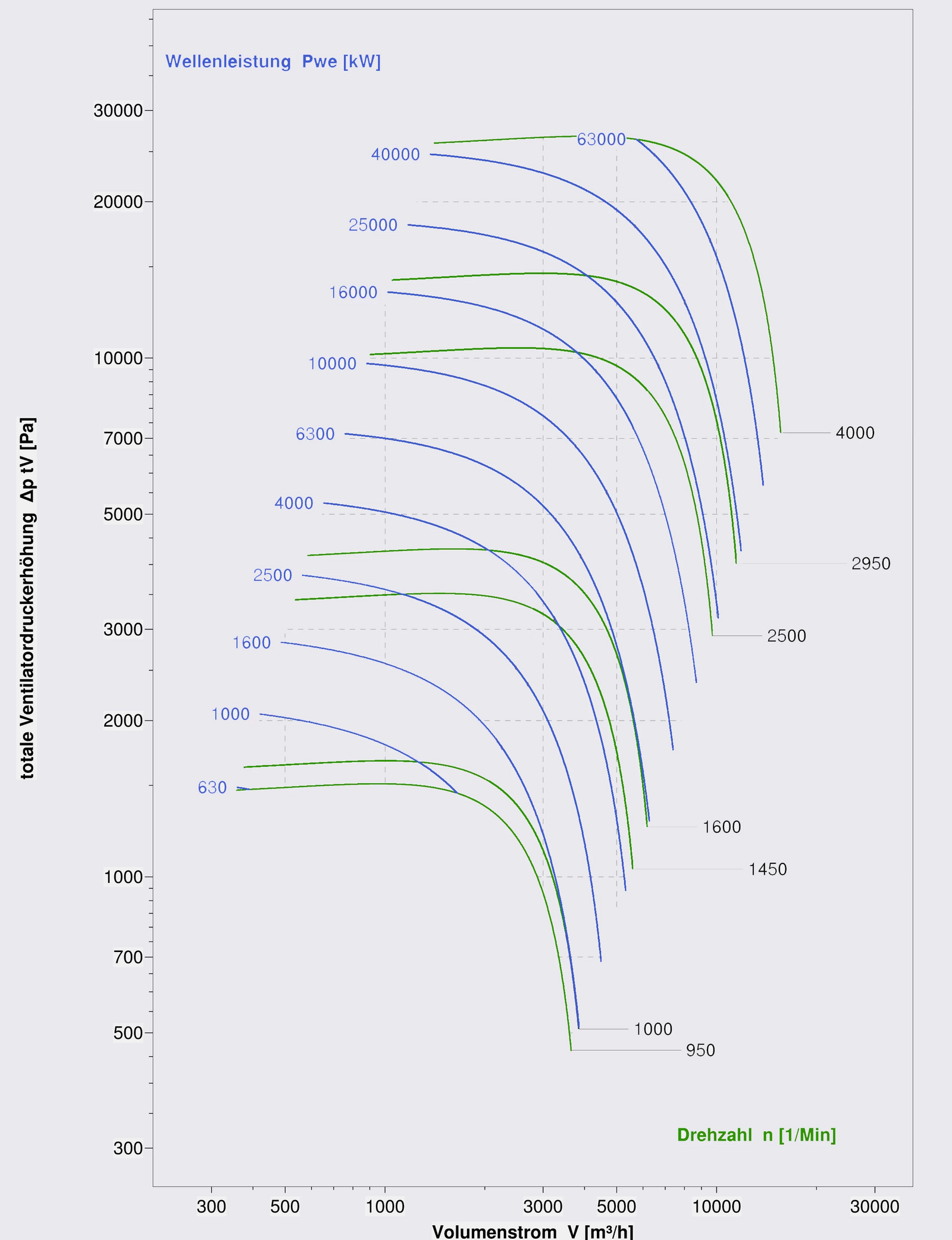

Frequency converters are primarily used for continuous control of the complete volume flow range of a fan outside of the grid frequency.

This allows the motor speed or the volume flow to be optimally adapted to the process requirement.

Technical advantage

This type of process control not only has a high energy-saving potential, but also protects the fan from mechanical wear through soft starting.

In addition to the conventional analog signal, the frequency inverters are optionally available with a variety of communication options (fieldbus systems) and can thus be integrated into any application control.

The following fieldbus communications are available as options:

CANopen, EtherCAT, EtherNet, Modbus, Profibus, Profinet and Sercos.

Compared to an inverter in the control cabinet, this decentralized solution reduces the costs for wiring and installation and by eliminating the shielded motor cable.

Despite the above-mentioned advantages of a decentralized solution, it is not always possible to do without a frequency converter in the control cabinet, e.g. for applications in the ATEX area. For this reason, we also supply frequency converters for control cabinets, which we adapt and pre-parameterize exactly to customer requirements.

(Kopie 5)